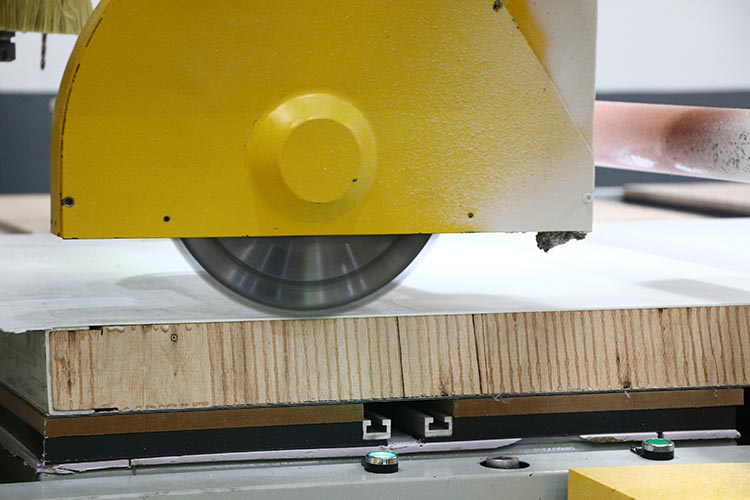

- After the cargo body panels are manufactured, they must undergo a series of secondary processing steps, including precision cutting, drilling, milling, slotting, and edge grinding, to meet structural and assembly requirements.

- When dealing with large-format panels and high-volume production, traditional manual processing is inefficient, inconsistent, and unable to meet modern quality standards. In contrast, large-scale CNC machining equipment offers a highly efficient and accurate solution for panel processing.

- By utilizing advanced CNC machining centers, cargo body panels can be processed with high dimensional accuracy, repeatability, and excellent edge quality. Complex geometries, mounting holes, hinge slots, and reinforcement areas can all be completed in a single setup, significantly reducing labor costs and processing time.

- CNC machining not only improves production efficiency and consistency but also ensures precise panel fitment during cargo body assembly. This results in faster installation, improved structural integrity, and enhanced overall durability of the cargo body system.

- With automated CNC processing, manufacturers can achieve stable mass production while maintaining strict quality control, making it an essential technology for modern cargo body panel fabrication.

Advantages of TOPOLO-TRUCK in CNC machining

Large-Scale Machining Platform

TOPOLO-TRUCK is equipped with an oversized CNC processing platform measuring up to 12 meters in length and 3 meters in width, specifically designed for large-format truck composite panels. This allows full-size cargo body panels to be machined in a single setup, eliminating the need for secondary positioning or splicing. As a result, overall processing accuracy is improved while production time is significantly reduced.

Five-Axis Simultaneous Machining Technology

Advanced five-axis CNC machining technology enables simultaneous multi-directional processing, delivering higher speed and superior precision compared to conventional three-axis systems. Complex contours, angled holes, chamfers, grooves, and special cutouts can be completed in one continuous operation. This not only ensures tighter tolerances and smoother surface finishes, but also enhances structural consistency across large batch production.