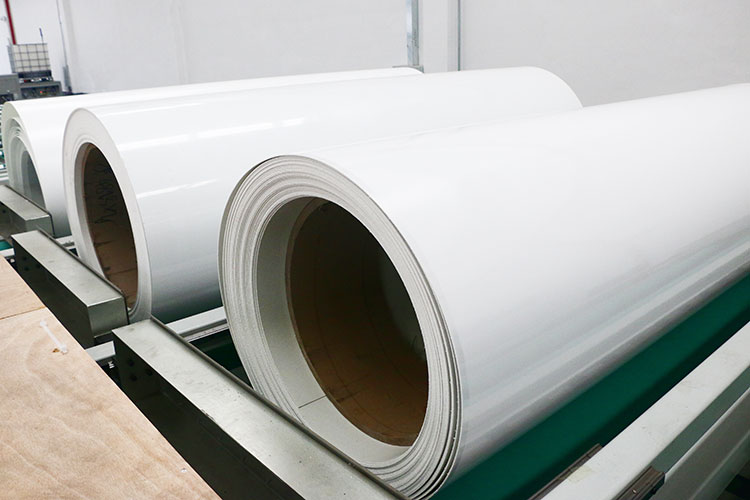

Los materiales de la piel de la carrocería refrigerada incluyen chapa de aluminio, chapa de acero inoxidable, chapa de acero pre-revestida, chapa de FRP, etc., pero la más popular es la chapa de FRP, que también es la configuración estándar de muchos camiones refrigerados.

FRP Sheet

FRP Skin PU foam sandwich panel for Refrigerated truck body

What are the advantages of FRP panels?

- Thermal insulation

There is low thermal conductivity with FRP, and the refrigerated truck box made of FRP sandwich panels with good thermal insulation performance.

- Waterproof

The gelcoat on the surface of FRP can effectively prevent moisture from infiltrating into the box.

- Lightweight

The density of FRP is much lower than that of various metal materials, which can make the composite panel of the refrigerated truck box lighter in weight.

- Easy to clean

The surface of FRP is flat and smooth, and it is not easy to attach stains. It is especially easy to clean the dirt attached to it, and various chemicals will not cause damage to it.

- Easy to repair

FRP is easy to repair, and the general damage and scratches on the surface of the refrigerated truck are easy to repair without obvious repair marks.

- Visual effect

The surface of refrigerated trucks using FRP composite panels usually has no obvious seams or gaps.

- Low cost

Regardless of material price or processing difficulty, FRP sandwich panels are lower than aluminum alloy or stainless steel composite panels.

Performance Parameters

| Performance Item | Unit | Reference Value | Certification Standard |

| Density | g/cm³ | 1.38 – 1.50 | GB/T1463 – 2005, ASTM D 792 |

| Barcol Hardness | Hbr | 30 – 60 | GB/T3857 – 87, ASTM D 2583 |

| Bending Strength | Mpa | 120 – 180 | GB/T1449 – 2005, ASTM D 790 |

| Bending Modulus | Mpa | 39 – 50 | GB/T1449 – 2005, ASTM D 790 |

| Charpy Impact Strength | KJ/m² | 30 – 50 | GB/T1449 – 2005, ASTM D 256 |

| Thermal Conductivity Coefficient | 10⁻⁵/°C | 0.15 – 0.32 | GB/T3139 – 2005, ASTM D 5470 |

| Wear Resistance Coefficient | mg/min | 4 | GB/T1689 – 2014, ASTM G115 |

| Temperature Range | °C | -40 – +120 | – |

| Water Absorption Rate | % | < 0.2 | – |

Thickness and Performance

| Item | 1.0mm | 1.5mm | 2.0mm | 2.5mm | 3.0mm |

| Weight (Kg/m2) | 1.5 | 2.25 | 3 | 3.75 | 4.5 |

| Glass content (%) | 19 | 25 | 29 | 30 | 30 |

| Tensile strength (Mpa) | 60 | 80 | 92 | 95 | 97 |

| Elongation at break (%) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Elastic modulus (Gpa) | 5.5 | 7 | 7.3 | 7.6 | 7.8 |

| Izod impact strength (KJ/m2) | 45 | 55 | 70 | 80 | 95 |